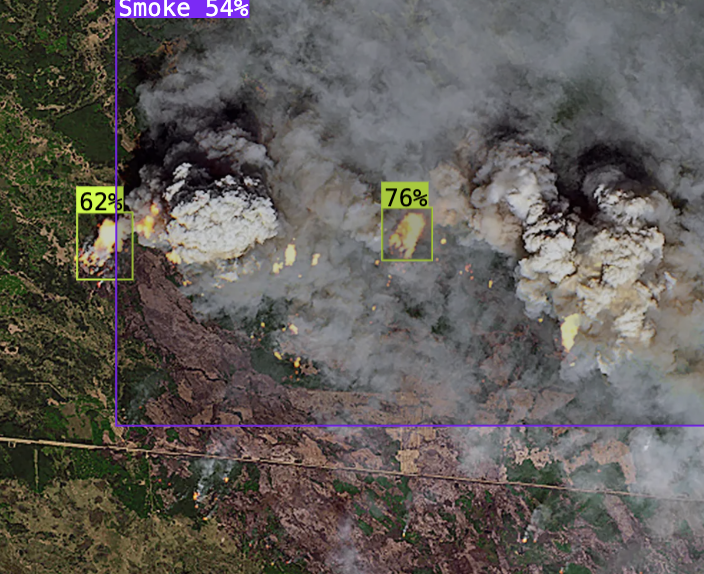

GOAL: Protect people and property by spotting wildfires sooner.

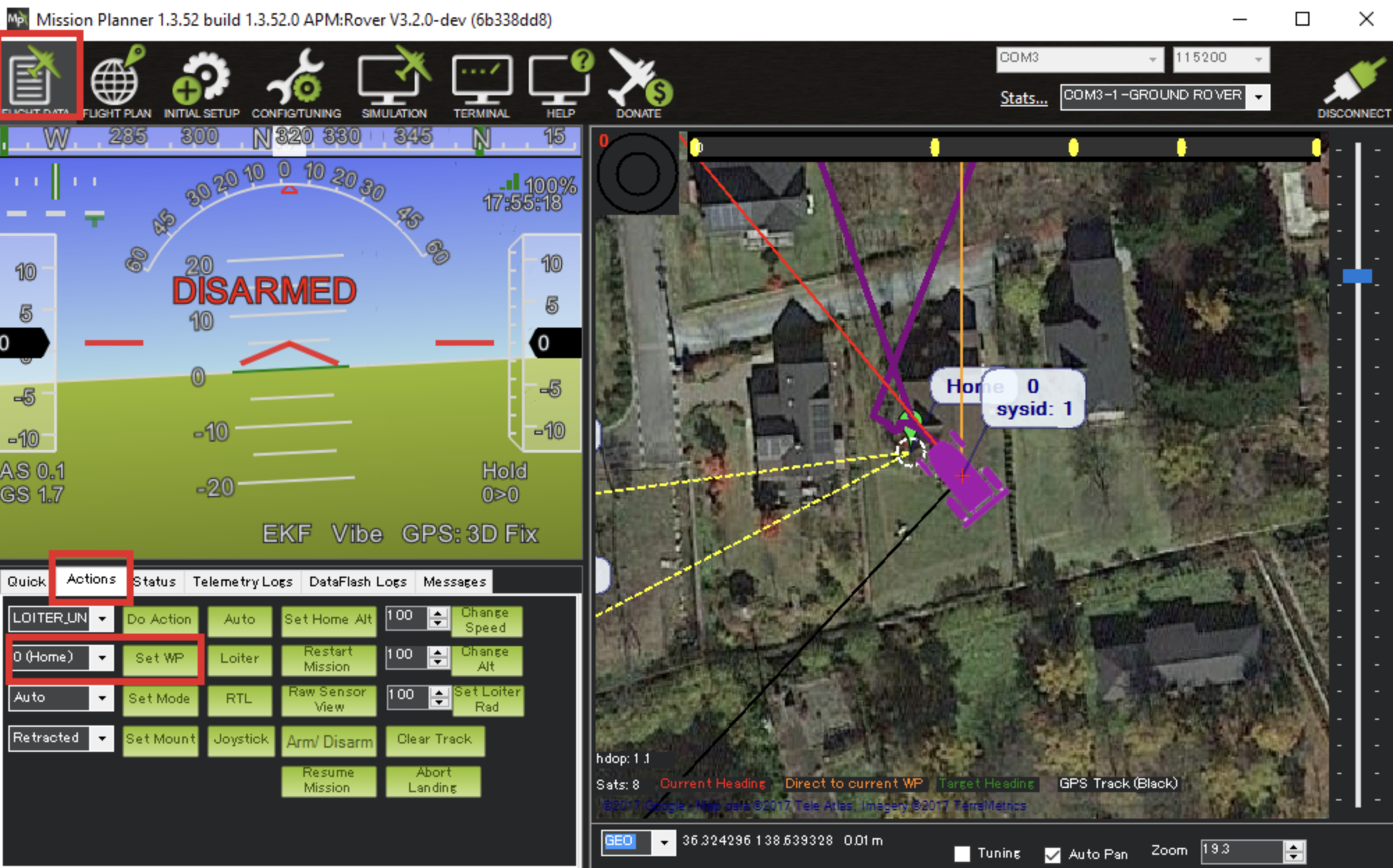

Using AI-powered pattern recognition, light-weight carbon fiber, autonomous navigation, advanced controls and solar power, the Stork will soon go into service.

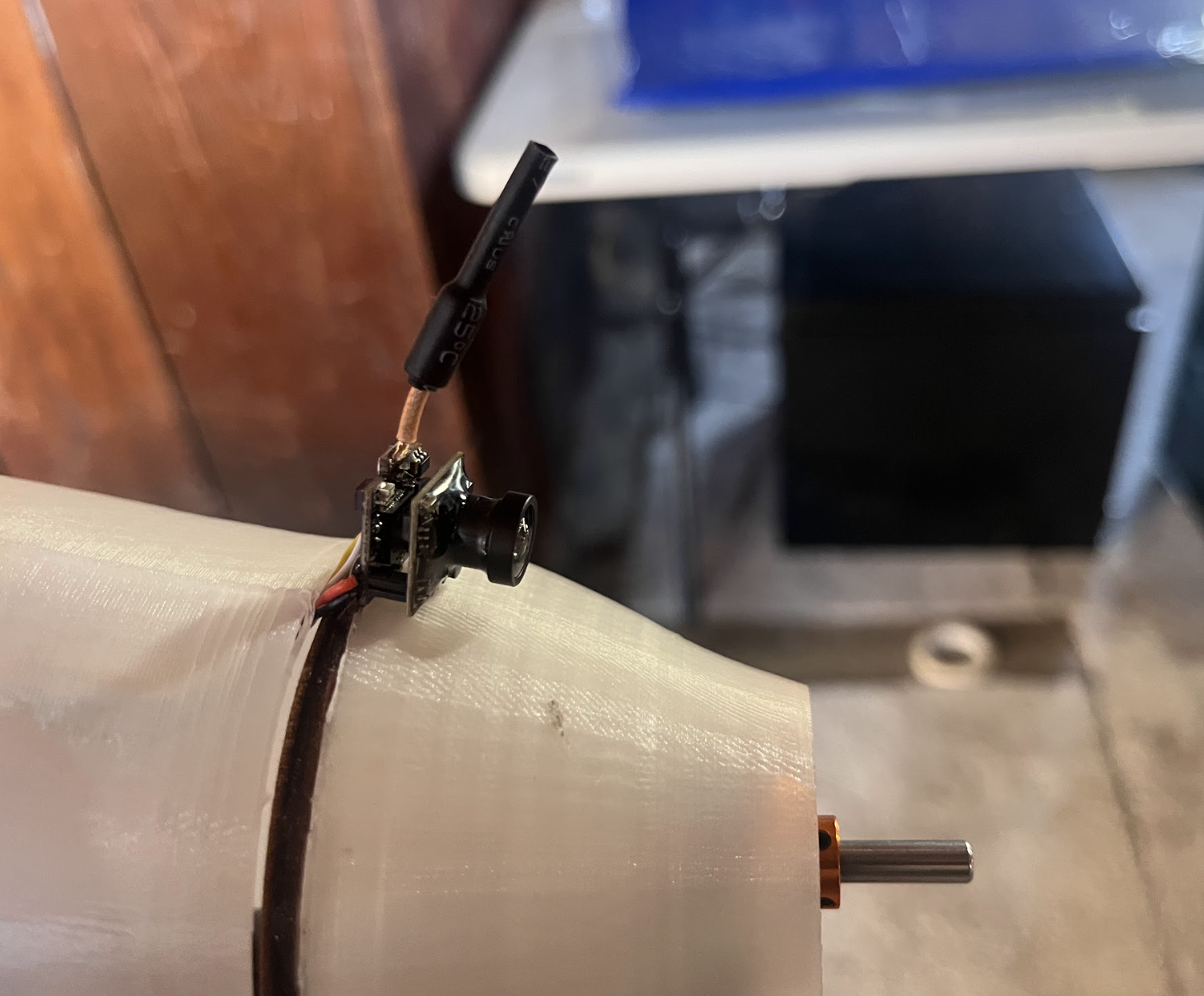

Systems

“WE DO THIS NOT BECAUSE IT IS EASY, BUT BECAUSE WE THOUGHT IT WOULD BE EASY.”

- A wise soul.

Want to get involved? Learn more about this project!

Setbacks

While I always understood that things never go according to plan in engineering, this project had more issues than I could have possibly imagined. There were failures due to low-quality products, incorrect design, and human error. I have learned that in order to be a great engineer, I have to separate my ego from my the success of the project. Engineering is about pushing the limits of our ability to invent new ideas, so never failing is in fact the mark of a bad engineer. Below is an abridged list of some of the challenges enountered:

-

Laser cutter being too small.

Insufficient space for equipment and fabrication.

Wood warping and fracturing.

Missing and damaged pieces of 3D printers.

Messing up wiring and all controls being mirrored.

Wood shifting while being cut.

Building before glue had arrived leading to seven broken pieces.

Once incorrectly measuring and glueing each airfoil 48.8 mm apart instead of 46.8 mm apart.

3D printer not accepting PVA for dissolvable support structures.

Laser cutter failing to cut foam board.

Foam not adhering to standard cyanoacrylate glue.

Mylar coating forming diagonal ripples when placed under too much tension, increasing drag.

Drilling a hole through a carbon fiber pipe at an angle leading to fracturing.

Carbon fiber pipes not being built to the manufacturer’s specifications.

Trailing ends of many airfoils flexing and breaking under tension.

Ailerons being too weak to torsion forces.

Mylar not sticking to itself when the airfoil was too thin.

-

Mac terminal failing to ping properly.

Project notes in Github being written in Turkish.

YOLO v8 not saving annotated images.

YOLO v8 not makoing identifications without a custom dataset.

All training data needing to be annotated by hand.

Operating service raising rates significantly above affordability for a teenager.

Terminal not recognizing Ardupilot.

Laser cutter breaking when running off-brand software.

Proprietary software not recognizing the laser cutter.

Camera system only connecting to Android phones.

Failing to complete project after two weeks of work!

-

Solar panels producing a fraction of the expected energy.

Making airfoils in CAD to be correct height but 17% too short, with the result they would not scale linearly.

Construction